Book Binding Edge Adhesive Hot Melt Adhesive

$3≥5Kilogram

| Payment Type: | L/C,T/T,Paypal,Others |

| Incoterm: | FOB,EXW,FCA,DDP,DDU |

| Min. Order: | 5 Kilogram |

| Transportation: | Ocean |

| Port: | hongkong,yantian, shenzhen |

$3≥5Kilogram

| Payment Type: | L/C,T/T,Paypal,Others |

| Incoterm: | FOB,EXW,FCA,DDP,DDU |

| Min. Order: | 5 Kilogram |

| Transportation: | Ocean |

| Port: | hongkong,yantian, shenzhen |

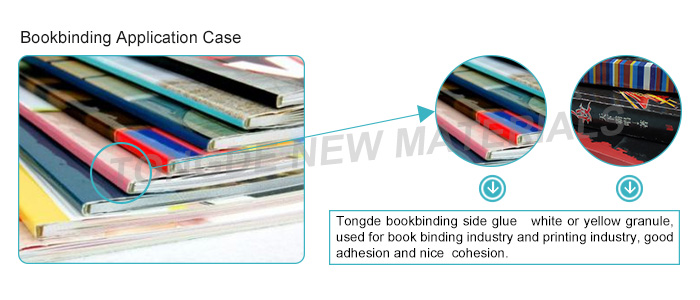

Model No.: 1052

Brand: TONGDE

Place Of Origin: China

Classification: Hot Melt Adhesives

Application Field: Construction, Fiber &Amp; Garment, Footwear &Amp; Leather, Packing, Transportation, Woodworking

Color: yellow

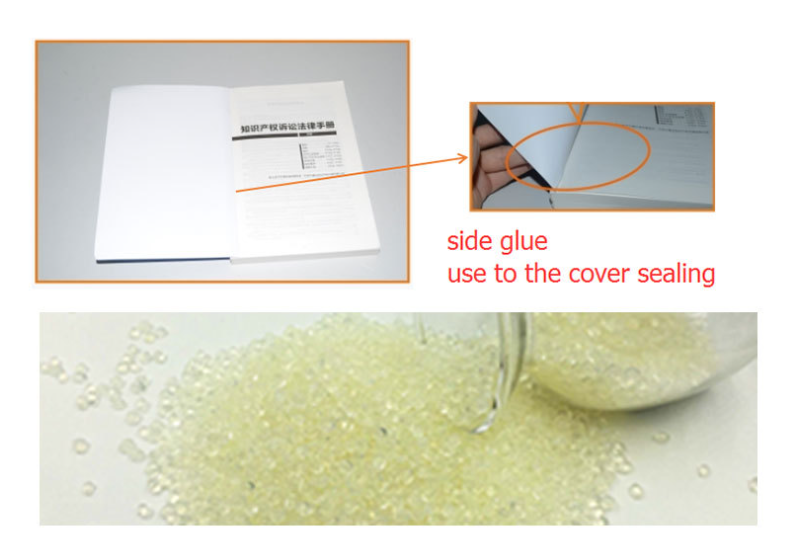

Usage: For books bonding

Preservation: Storage in clean and dry area

Shelf Life: 24 months

Package: 25kg/carton

Product Name: Book Binding Edge Adhesive Hot Melt Adhesive

The role of Hot Melt Adhesive in book binding

With the rapid development and rapid popularity of gluing machines, the requirements for book gluing in the industry are also increasing. Therefore, the choice of high-quality, high-performance Hot Melt adhesive has also become an important guarantee of the quality of the Binding Agent product.

First, the choice of hot melt adhesive

Printing factory can choose hot melt adhesive according to their actual binding needs. Book paper (such as student textbooks, books, magazines, etc.) binding, the actual production process, the printing factory can choose their own products according to their own production situation.

Second, the control of glue temperature is the key to ensure the printing of books and periodicals

During the use of hot melt adhesive, the use temperature of the adhesive should be controlled according to the normal production speed, workshop production environment temperature, temperature and product paper. When used, the glue temperature should be kept stable as far as possible, and it should not be high or low. At present, the glue temperature in the production process of the general printing plant is mostly controlled between 150 ° C and 180 ° C, and the fluidity and permeability of the glue are directly affected by the use temperature. When the use temperature is high, the fluidity of the adhesive liquid is good, the permeability is strong, but the bonding strength becomes low. At the same time, it may affect the amount of glue on the book and the thickness of the glue, long-term high temperature will cause the carbonization of the glue decomposition, resulting in aging phenomenon, affecting the quality of the binding, when the glue temperature is too low, the glue viscosity becomes larger, the fluidity is reduced, the permeability is weakened, directly affect the affinity between the glue and the paper, which is easy to cause the glue back is not full, and it is easy to scatter and drop pages.

The best use temperature should be slightly adjusted according to the temperature range provided by the manufacturer, not too high and too low. When used in summer, the temperature can be slightly lower, and vice versa in winter. When some printing plants are used in the summer, they often superimpose the room temperature on the temperature control display, and achieve the use temperature required by the manufacturer, which is completely wrong. Normal ambient temperature only has an effect on the cooling rate of the product after gluing. At present, the opening time of the glue is mostly 3-5 seconds, and the curing time is also completed in 1 second, which means that the product gluing process is basically completed in 13 seconds. After that, the book glue after forming further reduces the temperature, so as to achieve the ideal bonding effect.

Third, the control of the amount of glue is an important factor in the formation of the back

The control of the amount of glue is related to the thickness of the glue on the back of the book and the book box, which directly affects the bonding effect. In the production process, sometimes the first rubber wheel increases the amount of glue but there is no glue flower wheel phenomenon, if the amount of glue can not be used. Therefore, the amount of glue should be added in time, less frequent addition, reduce the impact on the glue temperature, or directly through the pre-sol pot for gluing.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.